Uninterruptible power supplies (UPS)

Introduction

An uninterruptible power supply, also uninterruptible power source, UPS or battery/flywheel

backup, is an electrical apparatus that provides emergency power to a load when

the input power source, typically mains power, fails. A UPS differs from an auxiliary

or emergency power system or standby generator in that it will provide near-instantaneous

protection from input power interruptions, by supplying energy stored in batteries,

supercapacitors, or flywheels. The on-battery runtime of most uninterruptible power

sources is relatively short (only a few minutes) but sufficient to start a standby

power source or properly shut down the protected equipment. A UPS is typically used

to protect hardware such as computers, data centers, telecommunication equipment

or other electrical equipment where an unexpected power disruption could cause injuries,

fatalities, serious business disruption or data loss. UPS units range in size from

units designed to protect a single computer without a video monitor (around 200

VA rating) to large units powering entire data centers or buildings

Common power problems

The primary role of any UPS is to provide short-term power when the input power

source fails. However, most UPS units are also capable in varying degrees of correcting

common utility power problems:

-

Voltage spike or sustained overvoltage

-

Momentary

or sustained reduction in input voltage

-

Noise,

defined as a high frequency transient or oscillation, usually injected into the

line by nearby equipment

-

Instability

of the mains frequency

-

Harmonic

distortion: defined as a departure from the ideal sinusoidal waveform expected on

the line

UPS units are divided into categories based on which of the above problems they

address and some manufacturers categorize their products in accordance with the

number of power-related problems they address

Technologies

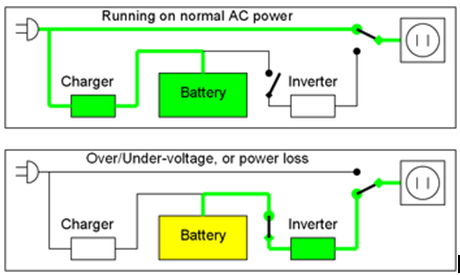

The three general categories of modern UPS systems are on-line, line-interactive

or standby.An on-line UPS uses a “double conversion” method of accepting AC input,

rectifying to DC for passing through the rechargeable battery (or battery strings),

then inverting back to 120 V/230 V AC for powering the protected equipment. A line-interactive

UPS maintains the inverter in line and redirects the battery’s DC current path from

the normal charging mode to supplying current when power is lost. In a standby (“off-line”)

system the load is powered directly by the input power and the backup power circuitry

is only invoked when the utility power fails. Most UPS below 1 kVA are of the line-interactive

or standby variety which are usually less expensive. For large power units, dynamic

uninterruptible power supplies are sometimes used. A synchronous motor/alternator

is connected on the mains via a choke. Energy is stored in a flywheel. When the

mains power fails, an Eddy-current regulation maintains the power on the load as

long as the flywheel’s energy is not exhausted. DUPS are sometimes combined or integrated

with a diesel generator that is turned on after a brief delay, forming a diesel

rotary uninterruptible power supply (DRUPS).

Offline/standby

The offline/standby UPS (SPS) offers only the most basic features, providing surge

protection and battery backup. The protected equipment is normally connected directly

to incoming utility power. When the incoming voltage falls below or rises above

a predetermined level the SPS turns on its internal DC-AC inverter circuitry, which

is powered from an internal storage battery. The UPS then mechanically switches

the connected equipment on to its DC-AC inverter output. The switchover time can

be as long as 25 milliseconds depending on the amount of time it takes the standby

UPS to detect the lost utility voltage. The UPS will be designed to power certain

equipment, such as a personal computer, without any objectionable dip or brownout

to that device.

Offline / standby UPS. Typical protection time: 0–20 minutes. Capacity expansion:

Usually not available

Line-interactive

The line-interactive UPS is similar in operation to a standby UPS, but with the

addition of a multi-tap variable-voltage autotransformer. This is a special type

of transformer that can add or subtract powered coils of wire, thereby increasing

or decreasing the magnetic field and the output voltage of the transformer. This

is also known as a Buck–boost transformer. This type of UPS is able to tolerate

continuous under voltage brownouts and overvoltage surges without consuming the

limited reserve battery power. It instead compensates by automatically selecting

different power taps on the autotransformer. Depending on the design, changing the

autotransformer tap can cause a very brief output power disruption. Which may cause

UPSs equipped with a power-loss alarm to “chirp” for a moment. This has become popular

even in the cheapest UPSs because it takes advantage of components already included.

The main 50/60 Hz transformer used to convert between line voltage and battery voltage

needs to provide two slightly different turns ratios: One to convert the battery

output voltage (typically a multiple of 12 V) to line voltage, and a second one

to convert the line voltage to a slightly higher battery charging voltage (such

as a multiple of 14 V). The difference between the two voltages is because charging

a battery requires a delta voltage (up to 13–14 V for charging a 12 V battery).

Furthermore, it is easier to do the switching on the line-voltage side of the transformer

because of the lower currents on that side. To gain the buck/boost feature, all

that is required is two separate switches so that the AC input can be connected

to one of the two primary taps, while the load is connected to the other, thus using

the main transformer’s primary windings as an autotransformer. The battery can still

be charged while “bucking” an overvoltage, but while “boosting” an under voltage,

the transformer output is too low to charge the batteries. Autotransformers can

be engineered to cover a wide range of varying input voltages, but this requires

more taps and increases complexity, and expense of the UPS. It is common for the

autotransformer to cover a range only from about 90 V to 140 V for 120 V power,

and then switch to battery if the voltage goes much higher or lower than that range.

In low-voltage conditions the UPS will use more current than normal so it may need

a higher current circuit than a normal device. For example to power a 1000-W device

at 120 V, the UPS will draw 8.33 A. If a brownout occurs and the voltage drops to

100 V, the UPS will draw 10 A to compensate. This also works in reverse, so that

in an overvoltage condition, the UPS will need less current.

Line-interactive UPS. Typical protection time: 5–30 minutes. Capacity expansion:

Several hours

Online/double-conversion

The online UPS is ideal for environments where electrical isolation is necessary

or for equipment that is very sensitive to power fluctuations. Although once previously

reserved for very large installations of 10 kW or more, advances in technology have

now permitted it to be available as a common consumer device, supplying 500 W or

less. The initial cost of the online UPS may be higher, but its total cost of ownership

is generally lower due to longer battery life. The online UPS may be necessary when

the power environment is “noisy”, when utility power sags, outages and other anomalies

are frequent, when protection of sensitive IT equipment loads is required, or when

operation from an extended-run backup generator is necessary. The basic technology

of the online UPS is the same as in a standby or line-interactive UPS. However it

typically costs much more, due to it having a much greater current AC-to-DC battery-charger/rectifier,

and with the rectifier and inverter designed to run continuously with improved cooling

systems. It is called a double-conversion UPS due to the rectifier directly driving

the inverter, even when powered from normal AC current. In an online UPS, the batteries

are always connected to the inverter, so that no power transfer switches are necessary.

When power loss occurs, the rectifier simply drops out of the circuit and the batteries

keep the power steady and unchanged. When power is restored, the rectifier resumes

carrying most of the load and begins charging the batteries, though the charging

current may be limited to prevent the high-power rectifier from overheating the

batteries and boiling off the electrolyte. The main advantage to the on-line UPS

is its ability to provide an electrical firewall between the incoming utility power

and sensitive electronic equipment.

Other designs

Hybrid topology / double conversion on demand

These hybrid designs do not have official designations, although one name used by

HP and Eaton is “double conversion on demand”.This style of UPS is targeted towards

high-efficiency applications while still maintaining the features and protection

level offered by double conversion.A hybrid (double conversion on demand) UPS operates

as an off-line/standby UPS when power conditions are within a certain preset window.

This allows the UPS to achieve very high efficiency ratings. When the power conditions

fluctuate outside of the predefined windows, the UPS switches to online/double-conversion

operation. In double-conversion mode the UPS can adjust for voltage variations without

having to use battery power, can filter out line noise and control frequency. Examples

of this hybrid/double conversion on demand UPS design are the HP R8000, HP R12000,

HP RP12000/3 and the Eaton BladeUPS.

Ferro-resonant

Ferro-resonant units operate in the same way as a standby UPS unit; however, they

are online with the exception that a ferro-resonant transformer is used to filter

the output. This transformer is designed to hold energy long enough to cover the

time between switching from line power to battery power and effectively eliminates

the transfer time. Many ferro-resonant UPSs are 82–88% efficient (AC/DC-AC) and

offer excellent isolation. The transformer has three windings, one for ordinary

mains power, the second for rectified battery power, and the third for output AC

power to the load.This once was the dominant type of UPS and is limited to around

the 150 kVA range. These units are still mainly used in some industrial settings

(oil and gas, petrochemical, chemical, utility, and heavy industry markets) due

to the robust nature of the UPS. Many ferro-resonant UPSs utilizing controlled ferro

technology may not interact with power-factor-correcting equipment.

DC power

A UPS designed for powering DC equipment is very similar to an online UPS, except

that it does not need an output inverter. Also, if the UPS’s battery voltage is

matched with the voltage the device needs, the device’s power supply will not be

needed either. Since one or more power conversion steps are eliminated, this increases

efficiency and run time. Many systems used in telecommunications use an extra-low

voltage “common battery” 48 V DC power, because it has less restrictive safety regulations,

such as being installed in conduit and junction boxes. DC has typically been the

dominant power source for telecommunications, and AC has typically been the dominant

source for computers and servers. There has been much experimentation with 48 V

DC power for computer servers, in the hope of reducing the likelihood of failure

and the cost of equipment. However, to supply the same amount of power, the current

would be higher than an equivalent 115 V or 230 V circuit; greater current requires

larger conductors, or more energy lost as heat. Most PCs can be powered with 325

V DC. This is because most ATX switching power supplies convert the AC input voltage

to approximately 325 V DC (230 × √2). On units with a voltage selector switch, the

115 V setting enables a voltage doubler that puts the top half of the AC wave in

one capacitor, and the bottom half in the other capacitor. This mode uses half of

the bridge rectifier and runs twice as much current through it. The 230 V setting

simply rectifies the AC using the full bridge rectifier, and puts it into both capacitors.

These two capacitors are hardwired in series. These power supplies can almost always

be safely run on 280–340 V DC long as the selector is in the 230 V position. They

will not work at all with DC power in the 115 V position; with 162 V DC applied,

nothing will happen because only one capacitor is being charged; if 325 V is applied,

the fuse and a surge suppressor or capacitor will blow. Power supplies with Active-PFC

are usually auto-ranging and have no voltage selector switch. They usually have

one input capacitor; it is charged to 320-400 V DC by a boost-mode power supply

that is part of the PFC circuit. It is uncertain how various auto-ranging and Active-PFC

power supplies will respond to having DC power applied when they are expecting AC

50–60 Hz power. A laptop computer is a classic example of a PC with a DC UPS built

in. High voltage DC (380 V) is finding use in some data center applications, and

allows for small power conductors, but is subject to the more complex electrical

code rules for safe containment of high voltages.

Rotary

A rotary UPS uses the inertia of a high-mass spinning flywheel (flywheel energy

storage) to provide short-term ride-through in the event of power loss. The flywheel

also acts as a buffer against power spikes and sags, since such short-term power

events are not able to appreciably affect the rotational speed of the high-mass

flywheel. It is also one of the oldest designs, predating vacuum tubes and integrated

circuits. It can be considered to be on line since it spins continuously under normal

conditions. However, unlike a battery-based UPS, flywheel-based UPS systems typically

provide 10 to 20 seconds of protection before the flywheel has slowed and power

output stops. It is traditionally used in conjunction with standby diesel generators,

providing backup power only for the brief period of time the engine needs to start

running and stabilize its output. The rotary UPS is generally reserved for applications

needing more than 10,000 W of protection, to justify the expense and benefit from

the advantages rotary UPS systems bring. A larger flywheel or multiple flywheels

operating in parallel will increase the reserve running time or capacity. Because

the flywheels are a mechanical power source, it is not necessary to use an electric

motor or generator as an intermediary between it and a diesel engine designed to

provide emergency power. By using a transmission gearbox, the rotational inertia

of the flywheel can be used to directly start up a diesel engine, and once running,

the diesel engine can be used to directly spin the flywheel. Multiple flywheels

can likewise be connected in parallel through mechanical countershafts, without

the need for separate motors and generators for each flywheel. They are normally

designed to provide very high current output compared to a purely electronic UPS,

and are better able to provide inrush current for inductive loads such as motor

startup or compressor loads, as well as medical MRI and cath lab equipment. It is

also able to tolerate short-circuit conditions up to 17 times larger than an electronic

UPS, permitting one device to blow a fuse and fail while other devices still continue

to be powered from the rotary UPS. Its life cycle is usually far greater than a

purely electronic UPS, up to 30 years or more. But they do require periodic downtime

for mechanical maintenance, such as ball bearing replacement. In larger systems

redundancy of the system ensures the availability of processes during this maintenance.

Battery-based designs do not require downtime if the batteries can be hot-swapped,

which is usually the case for larger units. Newer rotary units use technologies

such as magnetic bearings and air-evacuated enclosures to increase standby efficiency

and reduce maintenance to very low levels. Typically, the high-mass flywheel is

used in conjunction with a motor-generator system. These units can be configured

as:

-

A

motor driving a mechanically connected generator,

-

A

combined synchronous motor and generator wound in alternating slots of a single

rotor and stator,

-

A

hybrid rotary UPS, designed similar to an online UPS, except that it uses the flywheel

in place of batteries. The rectifier drives a motor to spin the flywheel, while

a generator uses the flywheel to power the inverter.

In case No. 3 the motor generator can be synchronous/synchronous or induction/synchronous.

The motor side of the unit in case Nos. 2 and 3 can be driven directly by an AC

power source (typically when in inverter bypass), a 6-step double-conversion motor

drive, or a 6-pulse inverter. Case No. 1 uses an integrated flywheel as a short-term

energy source instead of batteries to allow time for external, electrically coupled

genets to start and be brought online. Case Nos. 2 and 3 can use batteries or a

free-standing electrically coupled flywheel as the short-term energy source.

Applications

N+1

In large business environments where reliability is of great importance, a single

huge UPS can also be a single point of failure that can disrupt many other systems.

To provide greater reliability, multiple smaller UPS modules and batteries can be

integrated together to provide redundant power protection equivalent to one very

large UPS. “N+1” means that if the load can be supplied by N modules, the installation

will contain N+1 modules. In this way, failure of one module will not impact system

operation.

Multiple redundancy

Many computer servers offer the option of redundant power supplies, so that in the

event of one power supply failing, one or more other power supplies are able to

power the load. This is a critical point – each power supply must be able to power

the entire server by itself. Redundancy is further enhanced by plugging each power

supply into a different circuit (i.e. to a different circuit breaker). Redundant

protection can be extended further yet by connecting each power supply to its own

UPS. This provides double protection from both a power supply failure and a UPS

failure, so that continued operation is assured. This configuration is also referred

to as 1+1 or 2N redundancy. If the budget does not allow for two identical UPS units

then it is common practice to plug one power supply into mains power and the other

into the UPS.

Outdoor use

When a UPS system is placed outdoors, it should have some specific features that

guarantee that it can tolerate weather with no effect on performance. Factors such

as temperature, humidity, rain, and snow among others should be considered by the

manufacturer when designing an outdoor UPS system. Operating temperature ranges

for outdoor UPS systems could be around −40 °C to +55 °C. Outdoor UPS systems can

be pole, ground (pedestal), or host mounted. Outdoor environment could mean extreme

cold, in which case the outdoor UPS system should include a battery heater mat,

or extreme heat, in which case the outdoor UPS system should include a fan system

or an air conditioning system.

Internal systems

UPS systems can be designed to be placed inside a computer chassis. There are two

types of internal UPS. The first type is a miniaturized regular UPS that is made

small enough to fit into a 5.25-inch CD-ROM slot bay of a regular computer chassis.

The other type are re-engineered switching power supplies that utilize dual AC or

DC power sources as inputs and have built-in switching control units.

Machine standards

Measuring efficiency

The way efficiency is measured varies massively in the UPS market, and there are

a number of reasons for this. Many UPS manufacturers claim to have the highest level

of efficiency, often using different sets of criteria in order to reach these figures.

The industry norm can be argued to be anything between 93%-96% when a UPS is in

full operational mode, and to reach these figures companies often put their UPS

in an ideal scenario. Efficiency figures on site are often much closer to the 90%

mark, due to varying power conditions. The perfect scenario will never happen in

reality, due to ongoing voltage sags from the mains and the declining efficiency

of UPS batteries.

Warranty

Warranty on uninterruptible power supplies has varied over the past couple of years,

often depending if a machine is single phase or three phase. Few companies compete

on warranty, with the focus mainly on efficiency and maintenance contracts. The

standard manufacturer’s warranty is anything between 1–2 years and can even be limited

to certain aspects of the machine, often excluding the more expensive items such

as battery replacement. Focusing on one market, companies supplying three phase

however now offer lengthier warranties, with the norm closer to 2 years rather than

the single year.

Difficulties faced with generator use

Power factor

A problem in the combination of a “double conversion” UPS and a generator is the

voltage distortion created by the UPS. The input of a double conversion UPS is essentially

a big rectifier. The current drawn by the UPS is non-sinusoidal. This can cause

the voltage from the AC mains or a generator to also become non-sinusoidal. The

voltage distortion then can cause problems in all electrical equipment connected

to that power source, including the UPS itself. It will also cause more power to

be lost in the wiring supplying power to the UPS due to the spikes in current flow.

This level of “noise” is measured as a percentage of “Total Harmonic Distortion

of the current” (THD (i)). Classic UPS rectifiers have a THD (i) level of around

25–30%. To reduce voltage distortion, this requires heavier mains wiring or generators

more than twice as large as the UPS. There are several solutions to reduce the THD

(i) in a double conversion UPS:

Passive power factor correction:

Classic solutions such as passive filters reduce THD (i) to 5–10% at full load.

They are reliable, but big and only work at full load, and present their own problems

when used in tandem with generators.

Active power factor correction:

An alternative solution is an active filter. Through the use of such a device, THD

(i) can drop to 5% over the full power range. The newest technology in double conversion

UPS units is a rectifier that doesn’t use classic rectifier components (thyristors

and diodes) but high frequency components. A double conversion UPS with an IGBT

rectifier and inductor can have a THD (i) as small as 2%. This completely eliminates

the need to oversize the generator (and transformers), without additional filters,

investment cost, losses, or space.

Communication

Power management (PM) requires

-

The

UPS to report its status to the computer it powers via a communications link such

as a serial port, Ethernet and Simple Network Management Protocol, GSM/GPRS or USB

-

A subsystem in the OS that processes the reports and generates notifications, PM

events, or commands an ordered shut down. Some UPS manufacturers publish their communication

protocols, but other manufacturers use proprietary protocols.

The basic computer-to-UPS control methods are intended for one-to-one signaling

from a single source to a single target. For example, a single UPS may connect to

a single computer to provide status information about the UPS, and allow the computer

to control the UPS. Similarly, the USB protocol is also intended to connect a single

computer to multiple peripheral devices. In some situations it is useful for a single

large UPS to be able to communicate with several protected devices. For traditional

serial or USB control, a signal replication device may be used, which for example

allows one UPS to connect to five computers using serial or USB connections. However,

the splitting is typically only one direction from UPS to the devices to provide

status information. Return control signals may only be permitted from one of the

protected systems to the UPS. As Ethernet has increased in common use since the

1990s, control signals are now commonly sent between a single UPS and multiple computers

using standard Ethernet data communication methods such as TCP/IP. The status and

control information is typically encrypted so that for example an outside hacker

cannot gain control of the UPS and command it to shut down. Distribution of UPS

status and control data requires that all intermediary devices such as Ethernet

switches or serial multiplexers be powered by one or more UPS systems, in order

for the UPS alerts to reach the target systems during a power outage. To avoid the

dependency on Ethernet infrastructure, the UPSs can be connected directly to main

control server by using GSM/GPRS channel also. The SMS or GPRS data packets sent

from UPSs trigger software to shut down the PCs to reduce the load.

Batteries

The run-time for a battery-operated UPS depends on the type and size of batteries

and rate of discharge, and the efficiency of the inverter. The total capacity of

a lead–acid battery is a function of the rate at which it is discharged, which is

described as Peukert’s law. Manufacturers supply run-time rating in minutes for

packaged UPS systems. Larger systems (such as for data centers) require detailed

calculation of the load, inverter efficiency, and battery characteristics to ensure

the required endurance is attained.

Common battery characteristics and load testing

When a lead–acid battery is charged or discharged, this initially affects only the

reacting chemicals, which are at the interface between the electrodes and the electrolyte.

With time, the charge stored in the chemicals at the interface, often called “interface

charge”, spreads by diffusion of these chemicals throughout the volume of the active

material. If a battery has been completely discharged (e.g. the car lights were

left on overnight) and next is given a fast charge for only a few minutes, then

during the short charging time it develops only a charge near the interface. The

battery voltage may rise to be close to the charger voltage so that the charging

current decreases significantly. After a few hours this interface charge will spread

to the volume of the electrode and electrolyte, leading to an interface charge so

low that it may be insufficient to start the car. Due to the interface charge, brief

UPS self-test functions lasting only a few seconds may not accurately reflect the

true runtime capacity of a UPS, and instead an extended recalibration or rundown

test that deeply discharges the battery is needed. The deep discharge testing is

itself damaging to batteries due to the chemicals in the discharged battery starting

to crystallize into highly stable molecular shapes that will not re-dissolve when

the battery is recharged, permanently reducing charge capacity. In lead acid batteries

this is known as sulfation but also affects other types such as nickel cadmium batteries

and lithium batteries. Therefore it is commonly recommended that rundown tests be

performed infrequently, such as every six months to a year

Testing of strings of batteries/cells

Multi-kilowatt commercial UPS systems with large and easily accessible battery banks

are capable of isolating and testing individual cells within a battery string, which

consists of either combined-cell battery units (such as 12-V lead acid batteries)

or individual chemical cells wired in series. Isolating a single cell and installing

a jumper in place of it allows the one battery to be discharge-tested, while the

rest of the battery string remains charged and available to provide protection.

It is also possible to measure the electrical characteristics of individual cells

in a battery string, using intermediate sensor wires that are installed at every

cell-to-cell junction, and monitored both individually and collectively. Battery

strings may also be wired as series-parallel, for example two sets of 20 cells.

In such a situation it is also necessary to monitor current flow between parallel

strings, as current may circulate between the strings to balance out the effects

of weak cells, dead cells with high resistance, or shorted cells. For example, stronger

strings can discharge through weaker strings until voltage imbalances are equalized,

and this must be factored into the individual inter-cell measurements within each

string.

Series-parallel battery interactions

Battery strings wired in series-parallel can develop unusual failure modes due to

interactions between the multiple parallel strings. Defective batteries in one string

can adversely affect the operation and lifespan of good or new batteries in other

strings. These issues also apply to other situations where series-parallel strings

are used, not just in UPS systems but also in electric vehicle applications. Consider

a series-parallel battery arrangement with all good cells, and one becomes shorted

or dead:

-

The

failed cell will reduce the maximum developed voltage for the entire series string

it is within.

-

Other

series strings wired in parallel with the degraded string will now discharge through

the degraded string until their voltage matches the voltage of the degraded string,

potentially overcharging and leading to electrolyte boiling and outgassing from

the remaining good cells in the degraded string. These parallel strings can now

never be fully recharged, as the increased voltage will bleed off through the string

containing the failed battery.

-

Charging

systems may attempt to gauge battery string capacity by measuring overall voltage.

Due to the overall string voltage depletion due to the dead cells, the charging

system may detect this as a state of discharge, and will continuously attempt to

charge the series-parallel strings, which leads to continuous overcharging and damage

to all the cells in the degraded series string containing the damaged battery.

-

If

lead-acid batteries are used, all cells in the formerly good parallel strings will

begin to sulfate due to the inability for them to be fully recharged, resulting

in the storage capacity of these cells being permanently damaged, even if the damaged

cell in the one degraded string is eventually discovered and replaced with a new

one.

The only way to prevent these subtle series-parallel string interactions is by not

using parallel strings at all and using separate charge controllers and inverters

for individual series strings.

Series new/old battery interactions

Even just a single string of batteries wired in series can have adverse interactions

if new batteries are mixed with old batteries. Older batteries tend to have reduced

storage capacity, and so will both discharge faster than new batteries and also

charge to their maximum capacity more rapidly than new batteries. As a mixed string

of new and old batteries is depleted, the string voltage will drop, and when the

old batteries are exhausted the new batteries still have charge available. The newer

cells may continue to discharge through the rest of the string, but due to the low

voltage this energy flow may not be useful, and may be wasted in the old cells as

resistance heating. For cells that are supposed to operate within a specific discharge

window, new cells with more capacity may cause the old cells in the series string

to continue to discharge beyond the safe bottom limit of the discharge window, damaging

the old cells. When recharged, the old cells recharge more rapidly, leading to a

rapid rise of voltage to near the fully charged state, but before the new cells

with more capacity have fully recharged. The charge controller detects the high

voltage of a nearly fully charged string and reduces current flow. The new cells

with more capacity now charge very slowly, so slowly that the chemicals may begin

to crystallize before reaching the fully charged state, reducing new cell capacity

over several charge/discharge cycles until their capacity more closely matches the

old cells in the series string. For such reasons, some industrial UPS management

systems recommend periodic replacement of entire battery arrays potentially using

hundreds of expensive batteries, due to these damaging interactions between new

batteries and old batteries, within and across series and parallel strings.